Hey there. It has been awhile but I am keen to tell you about an amazing trip I took recently with my partner Chris. Or more specifically I want to share with you a visit to Japan and some papermaking! It has been in my travel dreams for some time and last March we finally got it all together and were able to go. Takao Moriki-San offered to meet us and take us to visit a papermaker. We had met Takao Moriki-San previously a couple of times through Nancy Jacobi owner of the Japanese Paper Place, he is a third generation paper exporter at Moriki Paper, and keen supporter of Japan's traditional papermakers. Kindly, Takao-San met us at a very busy subway station at rush hour to travel with us to Ogawa-Shi. The trip was about an hour and a half from our meeting point but I am not sure because the three of us chatted like old friends the whole journey, and I noticed because Japanese people don't really chat on public transit. : )

Anyhow, once we arrived at Ogawa-Shi, Tamakasa Kubo-San met us at the station in his car and drove us to the Saitama papermaking museum and workshop where people can work on their papermaking in a shared facility. There were a few people working while we were there and were happy to answer our questions. The museum was lovely and the blossoms on the trees on the grounds were about to burst. In 2014, Ogawa-Shi was designated UNESCO Intangible Cultural Heritage Status for keeping the ancient traditions of Japanese papermaking alive and well.

We went for a delightful traditional lunch where we had to remove our shoes (for the first time as this was only our second day in the country). I almost wiped out on the raised platform.

After lunch we went to Kubo-San’s paper making studio. Tamakasa Kubo-San is a fifth generation papermaker. We went to his studio where his mother, father and wife were hard at work making paper. Later we also saw the shop his grandfather built, which is a retail store, gallery and work space. They grow about 1/2 acre of domestic kozo (mulberry) to supplement what they purchase. The average age of a kozo farmer in Japan is 80+, so the future of the crop is uncertain. Kubo-San showed us raw materials and their differences, processing kozo, beating, mixing, etc. His wife and father were making sheets that day. It was absolutely mesmerizing to watch. They must have thought we were a bit simple, just staring at the process. We learned so much about the many stages in paper making and hope that all of our questions were good ones.

He showed us the steamed and peeled kozo bark and explained how rare and expensive the domestic kozo is. Korean,Thai and Philippine kozo is less expensive because they have a longer growing season and so can grow more, faster. The only drawback to the cheaper fibre is that because they are also more humid climates there is some naturally occurring waterproofing or oily material in the bark to protect the plant. This waxy deposit is found sporadically throughout the fibres and needs to be pulled out by hand while soaking. It is difficult to see as it is the same colour as the fibre but if it isn't removed it will turn brown or black later on and be a flaw in the finished paper.

Tamakasa-San has successfully integrated the use of domestic and imported kozo to try to keep the cost of the paper down while endorsing the domestic fibre. Tamakasa-San gave us this collection of bark fibres (above) for the store to show the different types of Japanese papermaking materials. From left to right: domestic kozo, Chinese kozo, Thai kozo, Chinese mitsumata and Philipine salago.

Here is the process in a nutshell: after harvesting, the bark is steamed and removed from the cut bush, the rough outer bark is then boiled off or peeled off to separate it from the prized inner bark, which is then soaked in water to soften, then it is cooked, pounded to break the fibre down, then put in the paper pulp grinder, and then into the bath with a hibiscus root jelly to help keep the slurry in suspension. To make a sheet, a screen frame is worked through the bath, picking up just the right amount of slurry and shaking the screen in different directions so that the fibers are laying in different directions to make the paper stronger, removed from the screen, and stacked, then dried on a board or on a heated metal wall. And voila! You have a sheet of washi. All steps done by hand with the help of a few simple belt-driven gadgets. There are a couple of videos that Chris took of the steps in my next post. He was very impressed with the lovely machines.

For this post, I have a few photos of the many stages in making a lovely piece of handmade Japanese paper.

Here we are examining some domestic kozo compared to some Thai kozo.

Soaking the mulberry and looking for any pieces that might have some wax in them that will need to be removed by hand.

Here is a lovely cushion and work area for working with the fibers after they have been softened with soaking.

This gorgeous window and vines in this building part of the paper making studios. Sigh.

Kubo-San making sheets of paper. This is Tamakasa Kubo-San's father.

A repetitive and meditative process, I think.

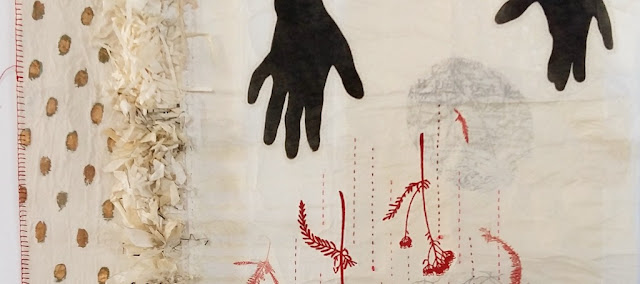

This is a photo of a display of lovely papers in Tamakasa Kubo-San's family shop/studio/ gallery. I wanted everything in there but didn't know how I could travel with it.

Here I am so excited and geeky after a wonderful day with these two cool guys (and Chris!), Takao Moriki-San (L) and Tamakasa Kubo-San (R) outside the shop/studio/gallery space.